testing steel hardness|hardness tester for metal : white label Hardness Testing of Metals: Rockwell, Brinell, Vickers, Knoop, and Leeb Tests. This article provides an overview of common hardness testing methods for metals, comparing . WEBINTEGRATION definition: 1. the action or process of successfully joining or mixing with a different group of people: 2.. Learn more.

{plog:ftitle_list}

Resultado da Sim, a Ultrafarma é confiável e realmente vale a pena comprar no site. No Reclame Aqui, o site aparece com uma boa avaliação, quase 100% dos chamados abertos foram atendidos e mais de 59% dos consumidores voltariam a comprar. No Ebit a Ultrafarma é loja Diamante e tem 96% de .

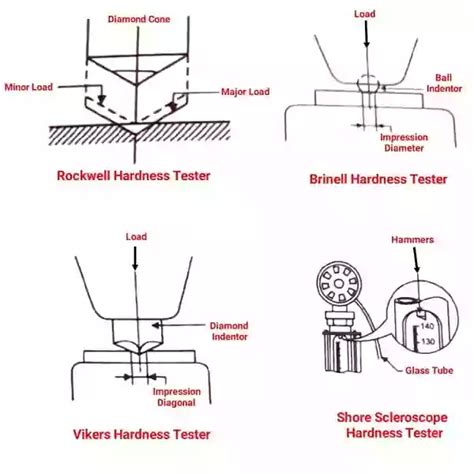

types of hardness testing methods

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .

Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Various hardness testing .

2005 chevy trailblazer low compression test

Hardness Testing of Metals: Rockwell, Brinell, Vickers, Knoop, and Leeb Tests. This article provides an overview of common hardness testing methods for metals, comparing . Hardness testing methods vary based on the material and heat treatment chosen. It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. Common . Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. In this article we shall explore five of the most common test methods for measuring the hardness of .How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the materials .

It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer the material, the deeper the ball will penetrate and vice versa.The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force.For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. .

Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond . Brinell hardness. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. .

In the Brinell test, a steel ball of 10 mm diameter is used as an indenter to create an impression on the test piece to calculate its Brinell hardness number. . Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10Learn more about material hardness testing. How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . To increase the hardness of the steel alloy. Mild steels (1045, A36) Alloy steels (4140, 4240) Tool steels (D2, A2, O1)The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. Industrial Application The Rockwell test is particularly suitable for measuring theIn materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

E45-18a(2023) Standard Test Methods for Determining the Inclusion Content of Steel . Indentation Hardness Testing. E140-12B(2019)e1 Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Indenter: 120 diamond cone or hardened steel ball. Rockwell hardness definition: 0.002mm residual indentation depth is a Rockwell hardness unit. K – constant, 130 for steel ball indenter and 100 for diamond .

3. Hardness Testing of Stainless Steel Pipes. Hardness testing is a critical quality control measure for stainless steel pipes, encompassing both welded and cold-drawn varieties. The testing methodology varies based on pipe dimensions and processing conditions to ensure accurate results.

Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: Employs a diamond penetrator to impress a sampleThe Jominy test (End Quench Test) is a standardized test procedure used to determine the hardenability of steel, and it can be performed using any Vickers micro hardness tester. The procedure is described in the following standards: ASTM A255 / ISO 642 / DIN 50191 / BS 4437 In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.Brinell hardness of Mild Steel . For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The test provides numerical results to quantify the hardness of a material, which is .

There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). . carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters. The Brinell .Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration . Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .

1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). Where: R eH is the upper yield strength; R m is the tensile strength; H RB is Rockwell hardness.. 2.1.2 Relative deviation analysis of conversion results. Based on the fitted quadratic regression model, the relative deviations between the converted values of upper yield strength and tensile strength and the results from the tensile test were calculated and .

A key component of Brinell hardness testers, these ball indenters are hard enough to make impressions on most metal. Made of carbide, they won’t deform as they press into hard material. Shallow indentations mean a material is hard and deep indentations show that it is soft. Use the diameter of the indentations created by these balls as part of the calculation to find your . There are 7 main types of hardness testers. Hardness testing is the procedure of testing the hardness characteristic of a material so properties such as strength, wear resistance, and ductility can be determined! Product Category; . 316L stainless steel: 140HV30; 347L stainless steel: 180HV30; Carbon steel: 55–120HV5; Iron: 30–80HV5 .

The Rockwell testing apparatus proved equally effective at finding the hardness of other steel alloys, metals and even non-metallic materials. The range of materials that could be tested for hardness with this apparatus was phenomenal, and hence a need arose to have different Rockwell scales to test different materials.Steel hardness is a critical parameter that directly influences a material's performance in various applications. Different scales, such as Rockwell C (HRC), Brinell (HB), Vickers (HV), and Rockwell B (HRB), are employed to quantify the hardness of steel and other metals. . Whether you're involved in materials testing, research and .

2 inch diameter, are used when testing materials such as steel-copper alloys, aluminum and plastics to name a few. Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft .

Testing the hardness of steels can be used an indication of how easily they can be manipulated, (formed, machined etc.), and how they will perform mechanically. Hardness test methods. Common tests for hardness in metals involve measuring the resistance to indentation by a hardened steel or diamond ball, cone or pyramid.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

2005 chevy trailblazer low compression test site forums.trailvoy.com

Resultado da 2 de mar. de 2017 · Cheat Engine Table for Supreme Ruler Ultimate. Credits: barbarian815, Yuee. Enjoy. --------------------------------------------------- .

testing steel hardness|hardness tester for metal